Second edition

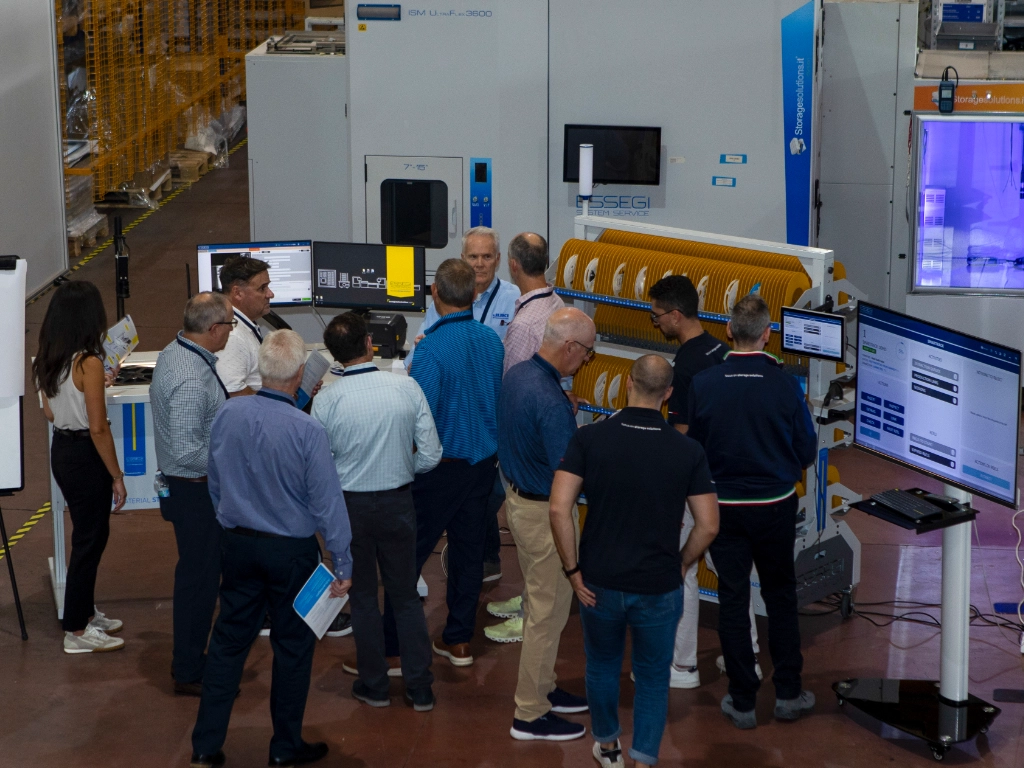

Essegi Automation’s Global Distribution Network gathered in Italy for the second edition of the Sales Meeting on September 25 and 26.

Distributors of our component storage and handling solutions joined us from China, Japan, USA, Europe, India, and more, to participate in this highly awaited biennial event dedicated to updating and training our representatives worldwide.

Two days of updates on new product solutions, technical deep dives, hands-on experimentation with marketing tools, and networking, as well as fun moments, such as dinner and the historical reenactment on the first evening, and an exploration of the region where Essegi Automation has made its 20-year-long history.

Surrounded by a timeless atmosphere, the castles of Juliet and Romeo in Montecchio Maggiore, chosen as the main location for the event, hosted a packed agenda of plenary sessions and thematic and technical workshops, some of which were also held at the company headquarters in Sovizzo, not far away.

Solutions Before Products

The concept of solution is not new (as evidenced by the organization of the menu on this website), but it’s worth reaffirming and testing it with the facts and the latest developments in Essegi Automation’s product offerings.

Where there is a problem, there is an opportunity and a solution.

Essegi Automation can make a difference!

Often, client companies are not aware of the critical issues along the assembly process and cannot identify root causes of production inefficiency on their own. This is where Essegi Automation steps in, well before the sales and installation of the machines, with its consultancy phase. While “consultancy” might be an overused term, it is incredibly appropriate in this case because the customized solution arises from a detailed study and in-depth analysis of the production context. Thanks to the modular nature of Essegi Automation’s storage systems and, more importantly, the flexibility of our ISM management and integration system, Essegi Automation can bring a tangible improvement to the efficiency of electronic assembly lines.

Consultancy and Analysis First

The importance of the pre-analysis phase in production contexts has allowed Essegi Automation to outline some recurring and paradigmatic production scenarios in the world of electronic assembly. Despite each production environment having its own specific characteristics, which Essegi Automation does not want to ignore, it is undeniable that various production realities share certain aspects and common issues.

For each of these scenarios, Essegi Automation has developed the most suitable solution to improve material flow and increase productivity, without disrupting the complex internal management balances of the company, but instead guiding it through a path of process optimization using ISM systems for recording, storing, and supplying production lines.

To illustrate these production scenarios, the meeting’s program included testimony from the Production Manager of CAME Group, interviewed alongside the Essegi Automation team that handled the installation and integration project of the storage systems, as well as a video of the Aster Elettronica case history. The latter was designed as a model for telling the story of other successful cases that will gradually be made available for consultation on our website.

New Product Updates

Now, let’s turn to the product innovations presented at this second edition of the Sales Meeting, where the distributors were able to first and foremost appreciate the versatility of the Ultraflex series in the Full Automation version, asking the machine to retrieve their gadget, which the AMR promptly picked up and delivered autonomously to the workshop participants!

While Ultraflex remained the highlight of the Demo, the undisputed stars of the hardware innovations focus were the new version of the Autoincoming Table and the Smart Rack Mobile, a product that addresses many immediate storage and supply needs near the production lines, perfectly integrated and integrable with the main storage and material registration systems.

On the software development front, many new functionalities of the ISM software were demonstrated during the workshop, which allowed the salespeople to peek behind the scenes at its workings, sharing the “control panel” of the software developers. One standout feature was the development of the Buffer solution for managing organized storage outside the main warehouse, near the assembly lines.

Finally, the workshop dedicated to exploring the integration capabilities of ISM systems clearly highlighted the extraordinary results of the introduction of the unique ID (see the Aster Elettronica case mentioned above) for complete component traceability with no margin for error.

It’s undeniable that organizing such a content-rich event corresponds to a significant effort from the entire company and those who collaborate closely with Essegi Automation. For this reason, our THANK YOU goes to everyone who contributed to the success of this second edition of the Global Sales Meeting.

The numerous demonstrations of appreciation and gratitude from our extraordinary distribution network, with whom we shared a truly intense experience, are testament to this. This event leaves a lasting mark and provides us with invaluable feedback to continue growing and better respond to an ever demanding and constantly evolving market!

See you at the next edition of the Global Sales Meeting in 2026!