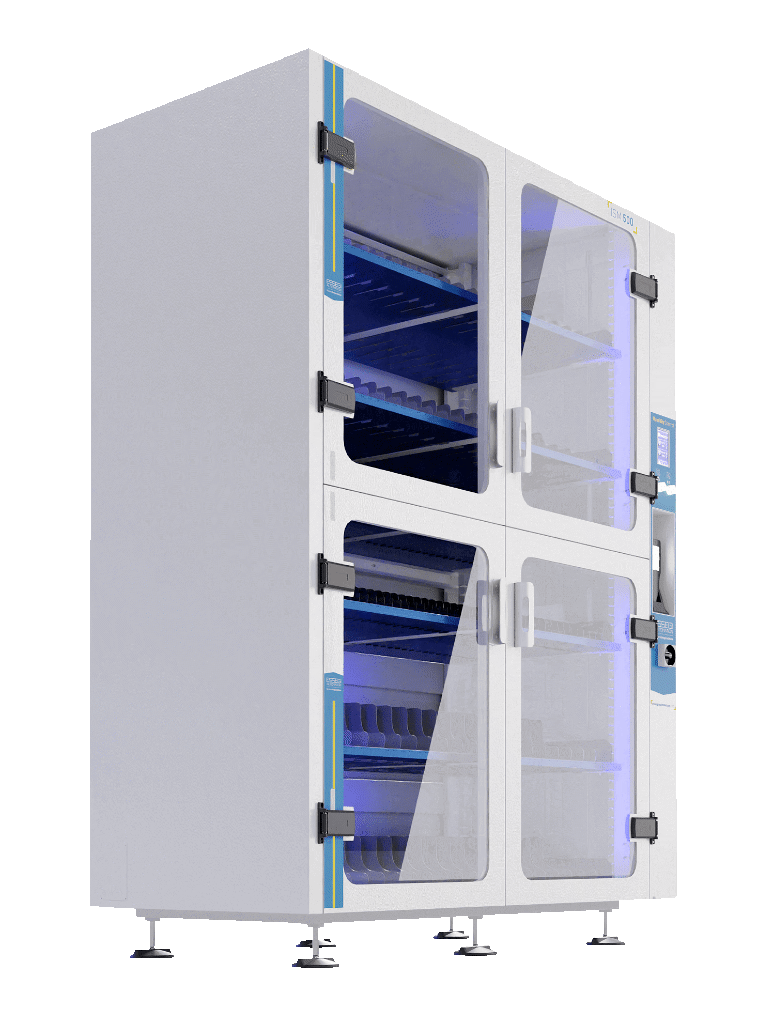

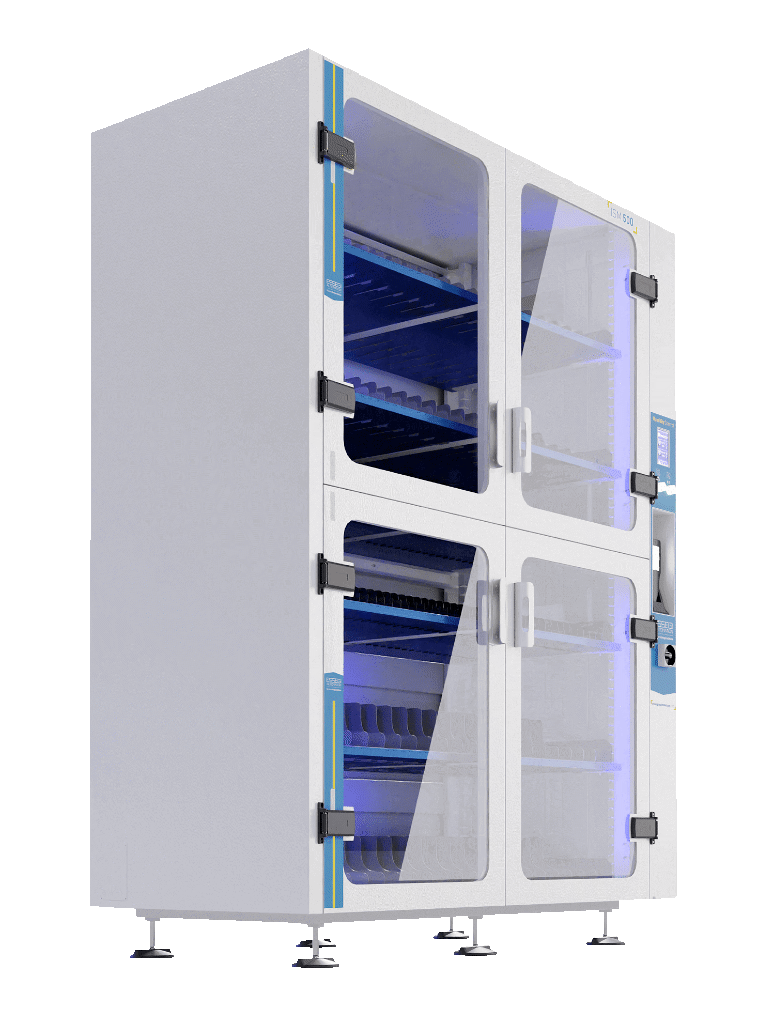

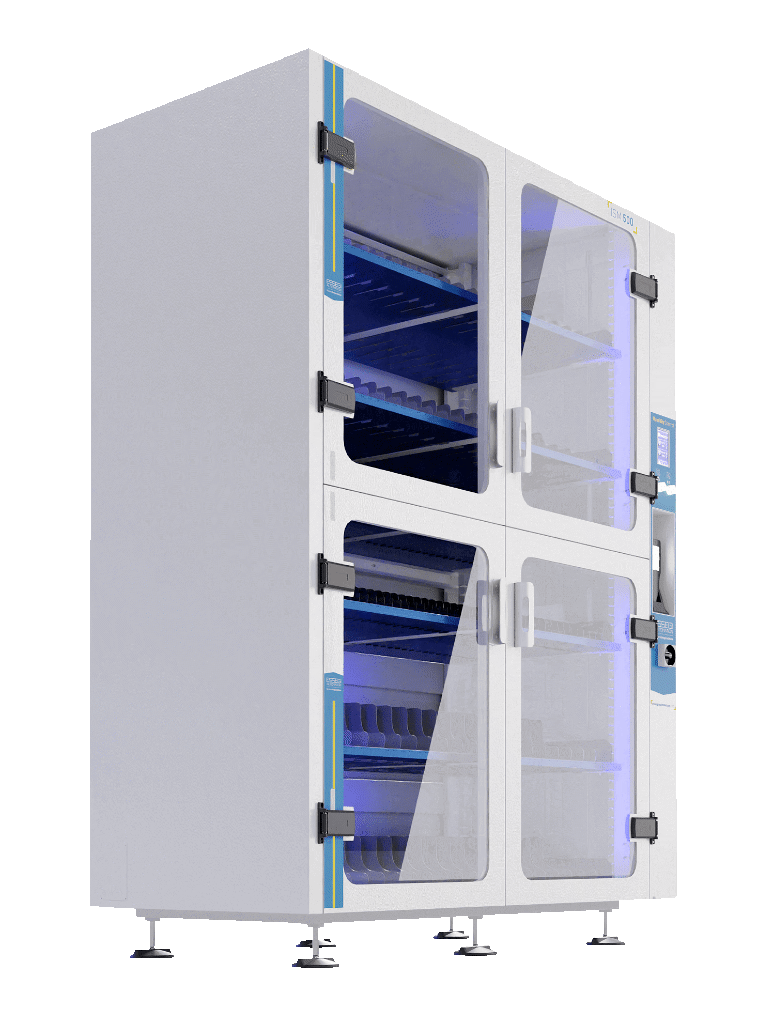

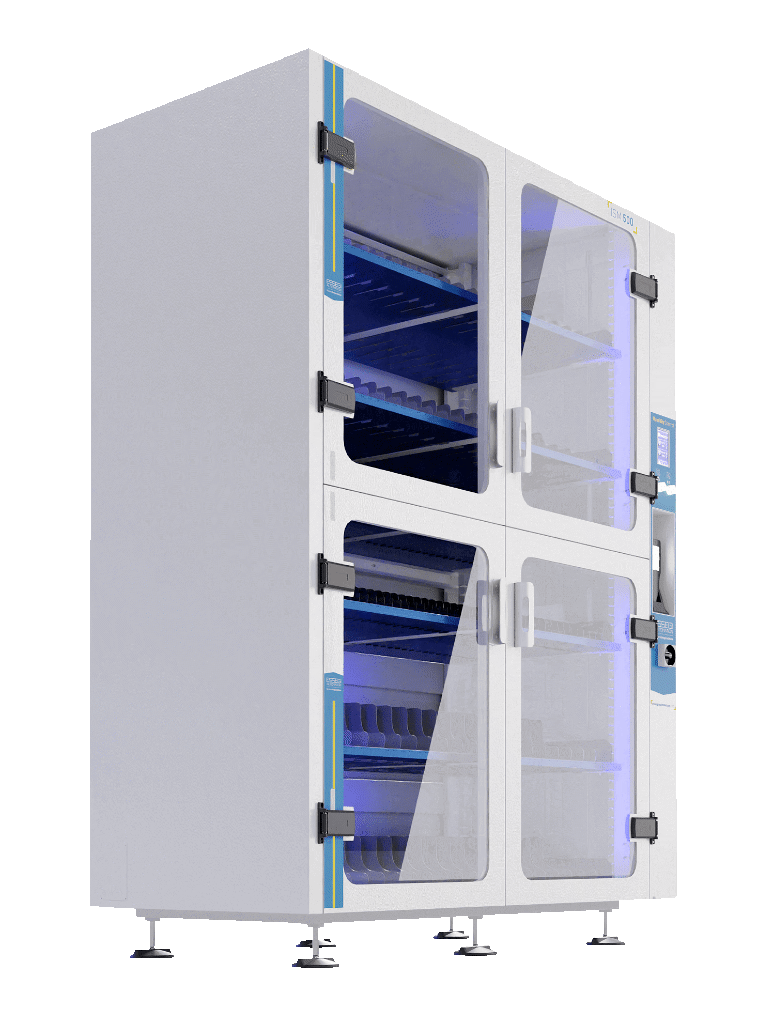

Pick to Light

The intelligent dynamic warehouse able to satisfy the storage needs of the most varied types of components, thanks to its configurable structure.

In the ISM 500 it is possible to insert 7/13/15″ reels, JEDEC trays, SMT and PTH tubes, screen printing frames and foils, printed circuits, PTH components, and much more.

- Available with different configurations (from 6 to 16 shelves)

- It offers the possibility of storing the most varied types of components: 7/13/15” reels, JEDEC trays, SMT and PTH tubes, screen printing frames and foils, printed circuits, PTH components, and much more.

- The shelves are equipped with a LED light system that guides the operator in the extraction of the material

- Separators and shelves and interiors are antistatic. ESD certificated

- Integrated standard humidity control

- The cabinet is available with electronic locks to ensure total safety

Benefits

What ISM 500 does:

Meets the storage needs of various types of components:

7/13/15″ reels, JEDEC trays, SMT and PTH tubes, screen printing frames and foils, printed circuits, PTH components

Guides the operator in the extraction and insertion of the material

Thanks to the PDA configuration, it guarantees the error-free management of the material inside the ISM500 warehouse and the external positions.

- Through an acoustic system, the PDAs guide the operator by giving a positive or negative feedback on the material being handled

- Through an LED system, the PDAs indicate to the operator which component is needed and must be extracted

- The software ensures that the reserve rolls can remain inside the warehouse until the call from the line. The extraction of the reels at the last, allows the MSL components to last longer within a totally protected environment.

- o After scanning the UNIQUE code of the label, a series of information appears on the PDA display that can further guide the operator

Control the humidity rate through the HCU 2.0 system

ISM 500 is designed to guarantee a continuous air treatment cycle. It regenerates the absorbed air without waste and the humidity extracted from the accumulation is expelled into the external environment.

The HCU 2.0 system is equipped with:

– 2 sensors: indoor/outdoor RH and indoor/outdoor temperature

– Display to show the indoor/outdoor relative humidity and temperature

It can also handle components that are not inside the ISM500

ISM500 is a small cabinet which, thanks to a software option, can manage and track the materials stored outside the ESSEGI Automation warehouses, inside traditional warehouses and shelving.

Check the external shelves or any other external position, as long as properly labelled (via barcodes). The software is able to identify and track the unique IDs stored in each location. It is mandatory to have a PDA to use external locations.

Versions and accessories

ISM 500 – Standard

Positions for 7″ reels, chip trays, splints etc

80 positions

Positions for 7″/13″/15″ reels, chip trays, splints etc

160 locations

Technical data sheet with the different storage capacity

ISM 500 – 10 shelves

Positions for 7″/13″/15″ reels, chip trays, splints etc

400 positions

Technical data sheet with the different storage capacity

ISM 500 – 16 shelves

Positions for cues etc

640 positions

Technical data sheet with the different storage capacity