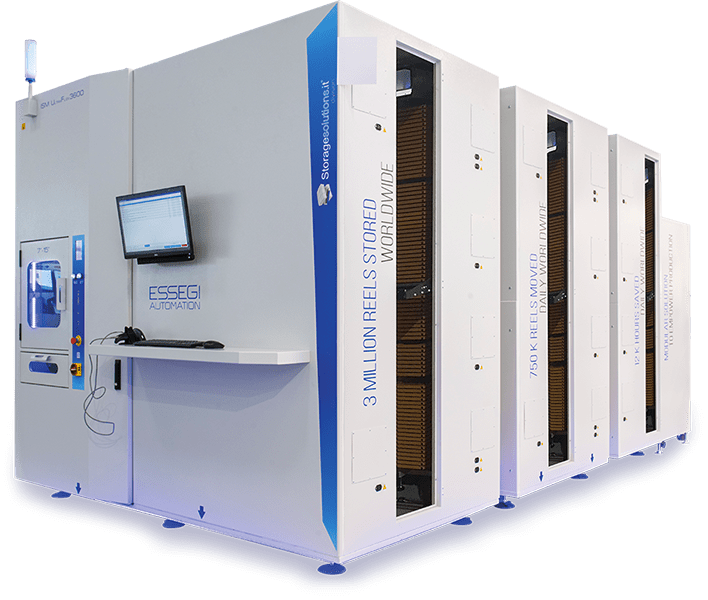

Ultraflex Series

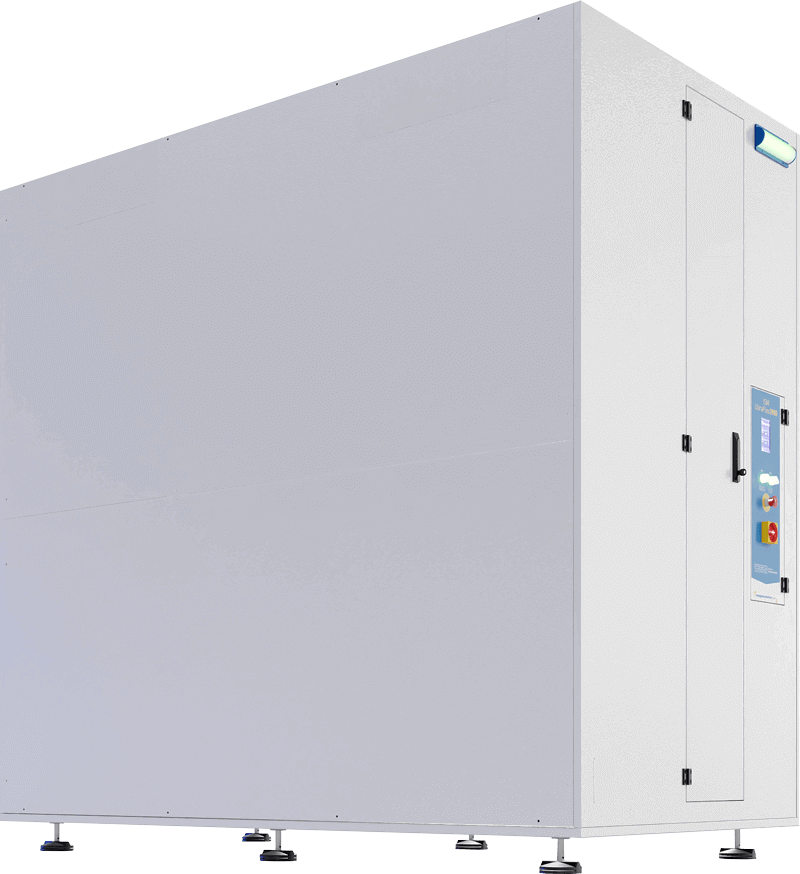

The automatic warehouses of Ultraflex series are the ideal solution for the storage and management of electronic production components.

They automate the receipt, archiving, traceability, picking from the warehouse and delivery to the production lines of the components necessary for electronic production with a decisive impact on the overall productivity of companies.

- They are super-compact, reaching a maximum height of 2.60 meters and a maximum width of 2.40 meters

- They are the only warehouses that manage and move the reels through a system of antistatic trays

- They are included with standard trays available in different sizes (from 7 “up to 15” configurable with different heights from 8 up to 88 mm)

- They come equipped with a kit of standard trays or can be customized to measure with quantities of customizable trays

- Internally, the spaces can be configured through customized design. A warehouse can contain: A warehouse can contain

- a mix of standard 7 “and 15″ reels trays (maximum capacity: 960 7 ” reels and 425 15″ reels)

- a completely customized mix of trays

- They are modular. They are created as standard to be modular and extendable through a system of conveyor “shuttles”, communicating doors, internal elevators and grippers for handling the reels.

- They can be configured with a range of advanced humidity control systems (RH <5%)

- They are equipped with light and sound systems that signal process progress or system anomalies (turret traffic lights)

- They are normally equipped with touch screen monitors / bar readers / keyboards and mouse

- They are equipped with high-precision cameras

Benefits

Versions and accessories

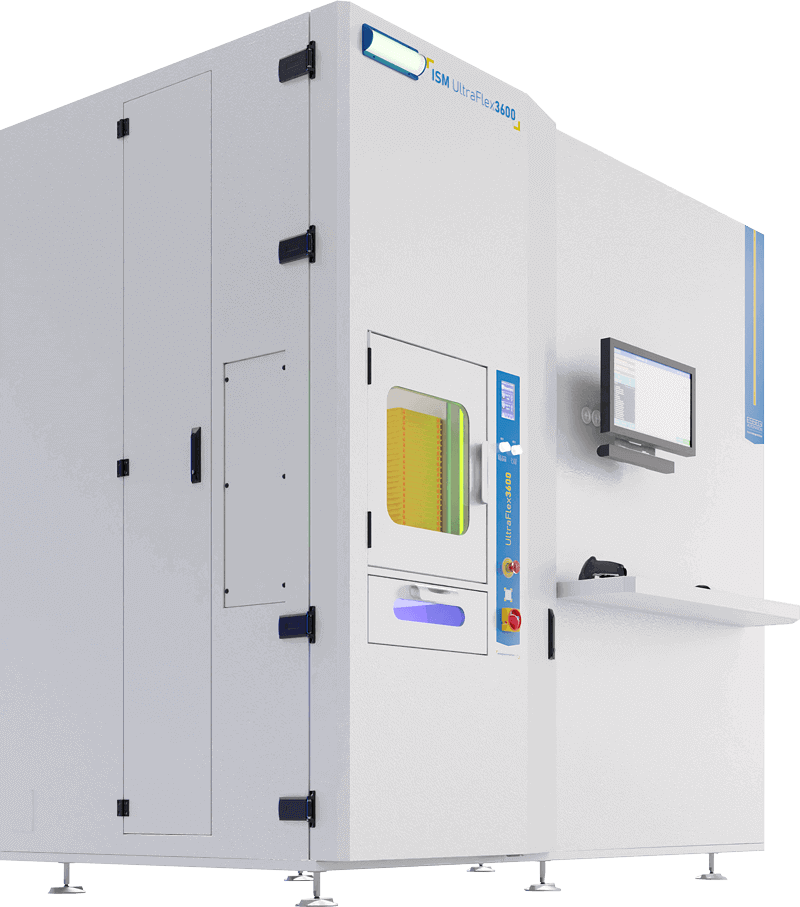

ISM UltraFlex 3600

Independent or integrated tower systems, with a capacity of up to 3600 reels per module.

Designed for ISM Ultraflex 3600 F.A., this system is made up of a unit carrying all case formats, fully integrated with AMR (Autonomous Mobile Robot)

This model is equipped with:

- Automatic recognition and management of all case formats

- Automatic loading and unloading with ISM 3600 F.A.

- Automatic alignment radar

Technical data sheet with the different storage capacity

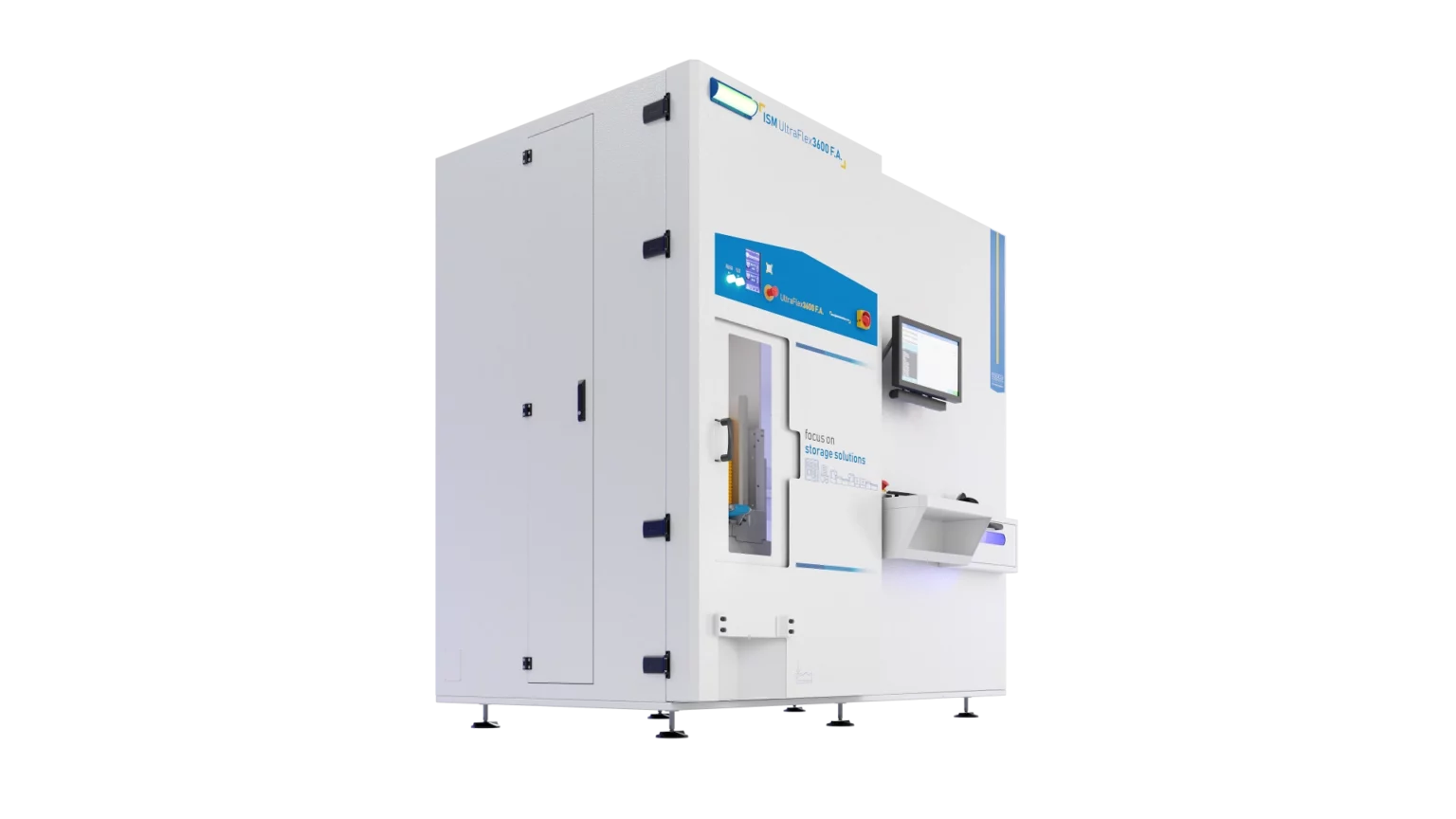

ISM UltraFlex 3600 F. A – Front Automation

Independent tower systems or integrated with other warehouses for automatic or manual front-loading and unloading.

This model comes equipped with:

- Automatic hands-free lift door

- Fast exit door

- Automatic recognition and management of all case formats

- Automatic loading and unloading with Autonomous Mobile Robots (AMR)

- Integrated PC with a touch screen display

- Included ISM Console Software

- Touch screen, keyboard and mouse

- External 1D/2D barcode scanner

- ESD certification

- Internal Dehumidification System (optional)

Technical data sheet with the different storage capacity

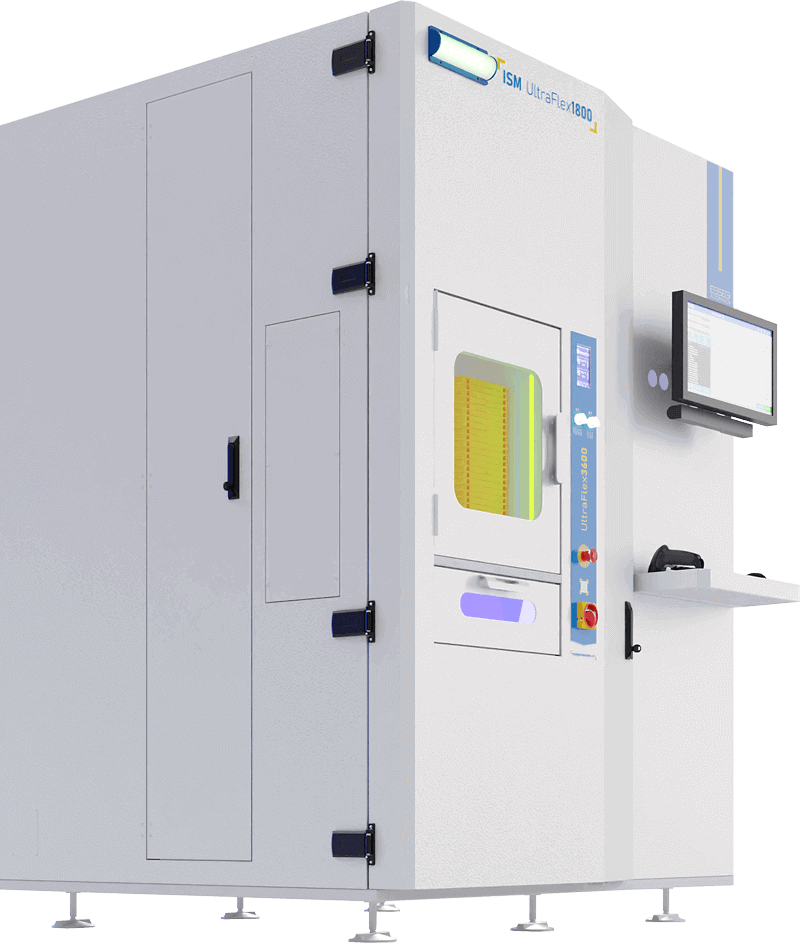

ISM UltraFlex 1800

Low-capacity systems suitable for industrial settings with lower production volumes, up to 1800 reels.

This model is equipped with:

- Multiple output port

- Quick exit door

- Integrated PC with touch display

- Internal computer

- An Ism Software console included

- Touch monitor, keyboard and mouse

- External 1D / 2D manual barcode scanner

- ESD certification

Independent unit, which does not necessarily have to be connected to another warehouse

Technical data sheet with the different storage capacity

ISM UltraFlex 3900

Expansion systems, ideal for increasing storage space and increasing component variety up to 3900 reels.

This model is equipped with:

- Integrated PC with touch display

- two shuttle connectors that allow connection to an ISM 3600 or another ISM 3900 of the same series

- ESD certification

NOT Standalone unit, it must be connected with an Ultraflex 3600 or an ISM 3900

Technical data sheet with the different storage capacity

ISM UltraFlex MIM – Multiple Interface Module

Connection system between storage warehouses and elevator modules.

The MIM is the connector between the UltraFlex series warehouses and the EEM elevators for fully automatic component loading. It supports up to three EEM elevators or two EEM elevators and an X-ray Component Counter.

This model is equipped with:

- Integrated PC with touch display

- two shuttle connectors that allow connection to an ISM 3600 or another ISM 3900

NOT Standalone unit, it must be connected with an ISM 3600 or an ISM 3900 o ISM EEM

Technical data sheet with the different storage capacity

Ism Ultraflex EEM – External elevator module

Elevator modules that enable fully automatic loading and unloading of components.

EEM allows automatic loading and unloading of material from UltraFlex warehouses. The loading / unloading of the material is carried out by the Case Carrier transport trolley which can be moved manually by the operator or by an AMR.

This model is equipped with:

- Exit / Entry door for multiple trays (up to 27 trays)

- Integrated PC with touch display

- Support for 10MPX or 20MPX camera

- ESD certification

NOT Independent Unit, it must be connected with a MIM

Technical data sheet with the different storage capacity

ISM Case carrier

Designed to transport Ultraflex series cases and facilitate the automatic loading/unloading of materials.

The Ism Ultraflex Case Carrier trolley is designed to transport Ultraflex series cases and is necessary to enable the automatic loading/unloading of materials to an EEM (Equipment Exchange Module). It can be used either manually by the operator or fully automated by an AMR (Autonomous Mobile Robot), also known as AGV (Automatic Guided Vehicle) or AIV (Automated Intelligent Vehicle).

This model is equipped with:

- Parking brake

- Latches

Technical data sheet with the different storage capacity

ISM Front AMR

Carrier system integrated with AMR (Autonomous Mobile Robot) designed for the automatic transport and loading/ unloading of Ultraflex series cases.

Designed for ISM Ultraflex 3600 F.A., this system is made up of a unit carrying all case formats, fully integrated with AMR (Autonomous Mobile Robot)

This model is equipped with:

- Automatic hands-free lift door

- Fast exit door

- Automatic recognition and management of all case formats

- Automatic loading and unloading with Autonomous Mobile Robots (AMR)

- Integrated PC with a touch screen display

- Included ISM Console Software

- Touch screen, keyboard and mouse

- External 1D/2D barcode scanner

- ESD certification

- Internal Dehumidification System (optional)

Technical data sheet with the different storage capacity

Configurations

How can our warehouses be combined?

Our systems are designed to be modular and scalable and to grow with businesses, allowing total freedom to configure, modify, expand and transfer to other departments or sites.

- ISM3600 can be used alone, independently or can be connected during the first installation, or at a later time even years later, to one or more ISM 3900.

- Two ISM 3600s can be connected to each other in the Back to Back configuration. This configuration is particularly useful when you want to separate the incoming and outgoing flows of the material or when you want to put two rooms in communication. Back-to-backs can transfer material from one side to the other via shuttle conveyors.

There are countless combination possibilities that we can propose or design directly according to the needs of the company.