Smart warehouse, lean production process.

Direct experience in the electronic assembly sector has taught us to go to the origin of production processes and to focus on storage management to make companies more efficient and competitive.

Essegi Automation develops integrated intelligent logistics solutions to create a lean system of handling and procurement of components throughout the entire assembly lines.

Our ISM system

Essegi Automation has created an innovative storage management system, through automatic warehouses capable of tracking and handling the components for the organized and efficient supply of SMT and THT production lines. A flexible and open ISM system, capable of communicating with all management systems and integrating perfectly into any highly interconnected production context, in line with the digital transformation in progress.

The advantages of technology

Essegi Automation

Our automated warehouses are the result of a careful analysis of the critical issues in the management of component storage which has led our specialists to develop a new technology that stands out by:

The innovation introduced by these elements, combined with the great flexibility of the management software, is what has allowed our solutions not only to solve the main production problems, but also to offer new growth prospects.

Dynamic Warehouses

Automatic Warehouses

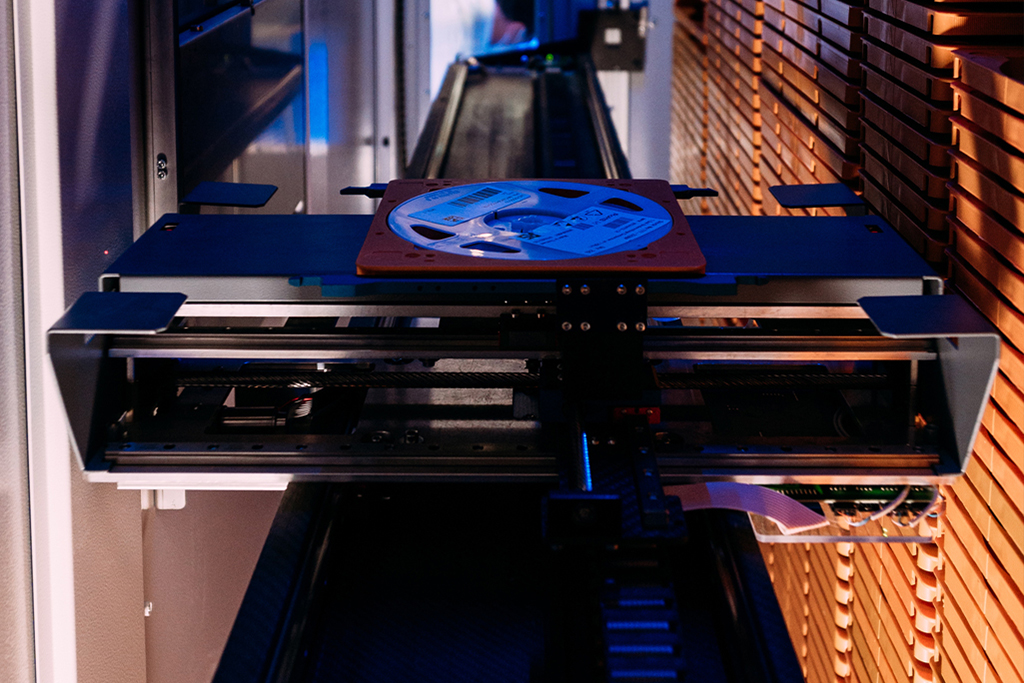

The Ultraflex series automatic warehouses are intelligent storage solutions conceived and designed for the electronics sector.

Our product range includes various electronic component storage solutions.

- ISM 3600: systems with capacities up to 3600 reels as independent towers or integrated with other warehouses.

- ISM 1800: reduced capacity systems suitable for industrial realities with lower production volumes. They can hold up to 1800 reels.

- ISM 3900: extendable systems, ideal for expanding storage space and increasing the mix of components.

Of the same series:

- ISM MIM: connection systems between storage warehouses and modules.

- ISM EEM: elevator modules that allow fully automatic loading and unloading of components.

- ISM CASE Carrier: trolleys for transporting the rolls. They can be moved either by hand by the operator or in a fully automated way by one or more AIV (Autonomous Intelligent Vehicles). They can be moved either by hand by the operator or in a fully automated way by one or more AIV (Autonomous Intelligent Vehicles).

Pick to Light Solutions

Dynamic Warehouses Pick to Light

The dynamic warehouses ISM 500 are the ideal solution for the dynamic storage of the most varied types of components.

- Up to 640 configurable internal positions.

- Ability to manage dynamic positions outside the warehouse.

- Mix of components: 7/13/15″ reels, JEDEC trays, SMT and PTH tubes, screen printing frames and films, printed circuits, PTH components, etc.

- Traceability They are equipped with LED light signals for each position and through the integrated use of PDA handheld readers, the incorrect removal of components is avoided.

- Humidity control to maintain an internal environment with relative humidity below 5%.

Incoming Material Station

Incoming Material Station

Incoming Material Station is the advanced solution for the management of the material in the acceptance phase that allows the receipt and the complete entry of management data in a single operation.

Thanks to the use of optical reading tools, the Table allows a considerable saving of time and a level of detail that allows the complete and simultaneous updating of the warehouse inventory for the purchasing office, planning and production. The table connects with the other Essegi Automation intelligent logistics management systems but also with the company management systems (ERP or MES) and with all the main brands of the Pick & Place lines.

Software

Software

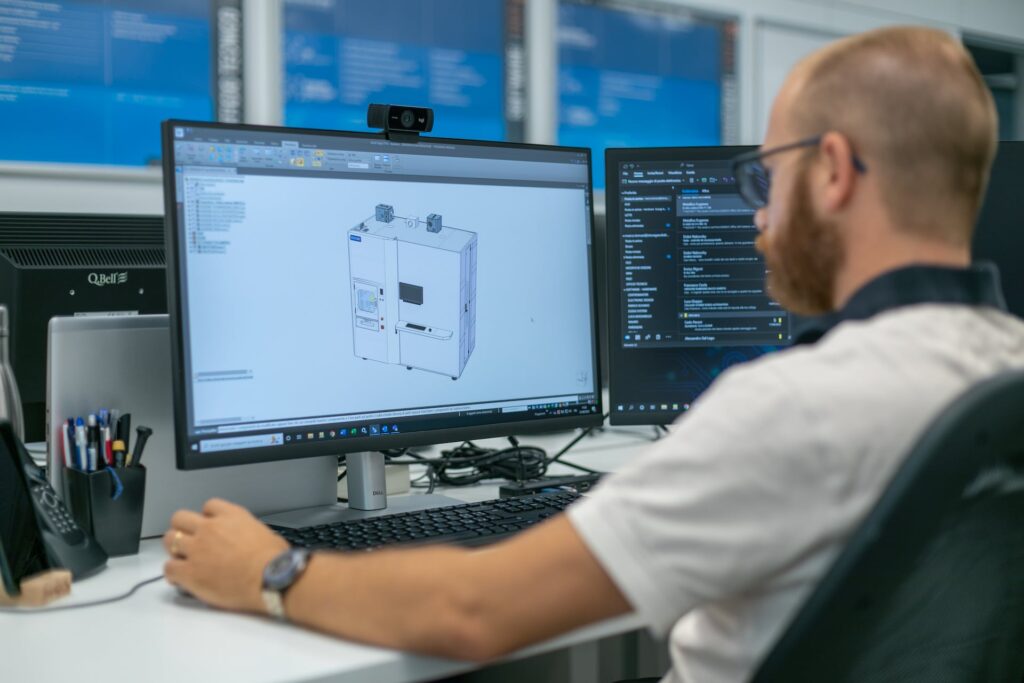

The ISM Essegi Automation software is the integrated management system of all the hardware elements that make up the Essegi solutions for the organization and rationalization of the operational logistics of companies producing electronic components.

An indispensable tool in our offer of advanced solutions, designed in detail to obtain full control of all the electronic components that move in the company.

ISM software is available with SPECIAL features:

- store the image acquired by the video camera inside the DATA BASE or in the Autoincoming Station.

- physically separate customer materials without reserving a special area of the warehouse.

- check for the presence of alternative components if a necessary component is not sufficient to complete the work or is not available.

- receive alerts from the SMT line to immediately generate a priority extraction queue and prepare the necessary material through the Ultraflex series warehouses.

- planning production with extreme flexibility to make changes at any time without ever losing control and availability of the material.