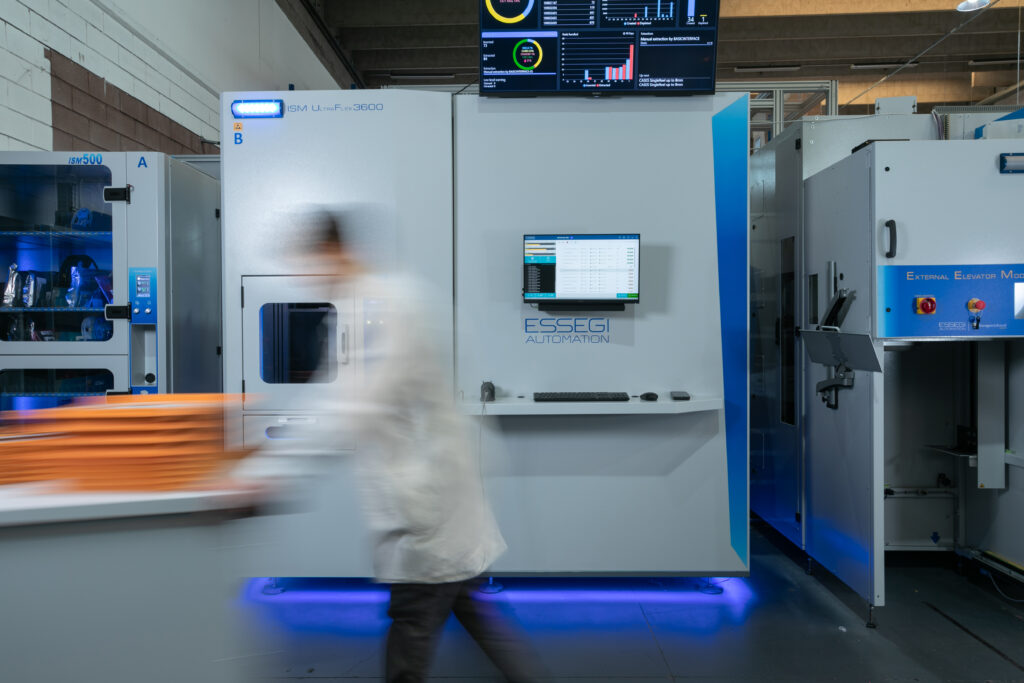

2,000 yellow flags on a global map. This is the achievement that Essegi Automation can proudly showcase today, almost 15 years since the installation of the first automated warehouse.

It should be noted that the first machine installed is by no means a museum piece but is still in operation at the company in Vicenza that was the first to adopt the new intelligent storage system for the reels of components used in electronic board production.

It is a bet won, demonstrating the reliability of a technology capable of meeting the needs of a rapidly transforming market due to its remarkable growth over these years.

Beyond storage in the global scenario

If 2,000 installations worldwide represent a milestone for Essegi Automation, it’s not just a matter of numbers.

This data, which has shown a consistent increase in recent years, paints a picture of a manufacturing market that is increasingly strategic in the global economic system. This puts electronic assembly companies under growing pressure to streamline and optimize production processes to meet rising demand and address supply chain challenges.

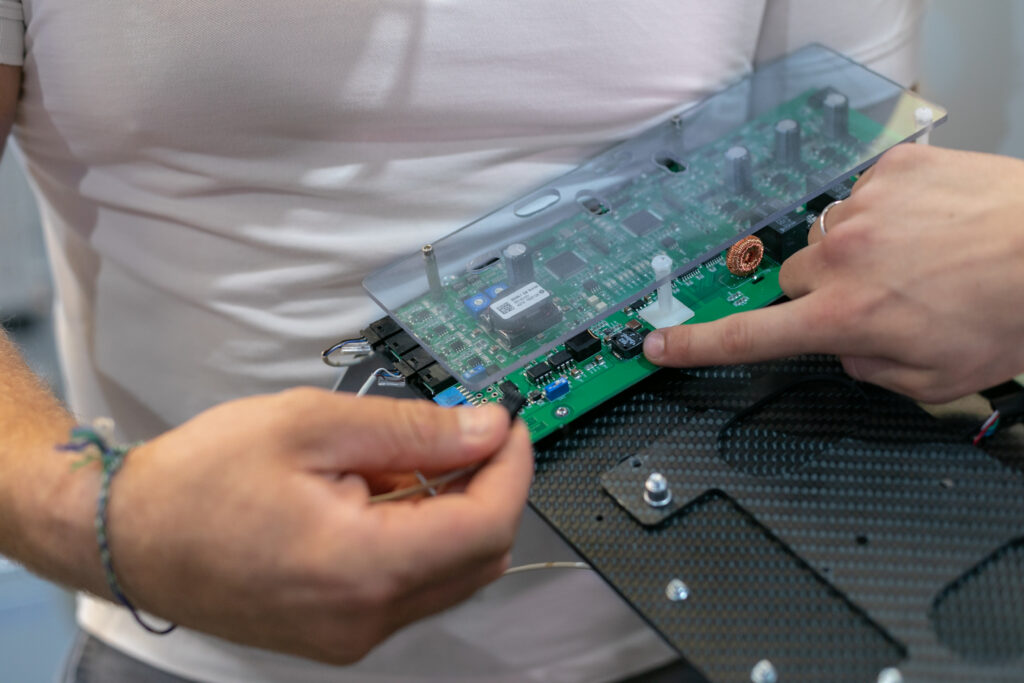

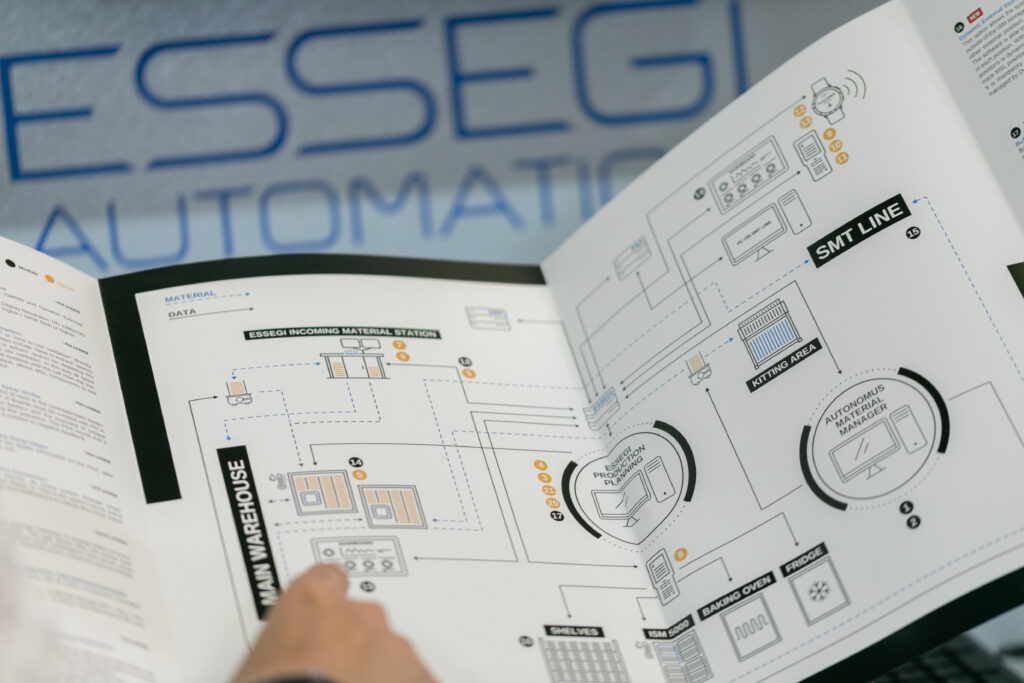

Since its inception, the Essegi Automation smart warehouse has been driven by a vision that goes beyond component storage and supply for production lines. It aims to foster the development of an integrated system for managing the entire production process, from material acceptance to the finished product.

The strength of a flexible and integrated system

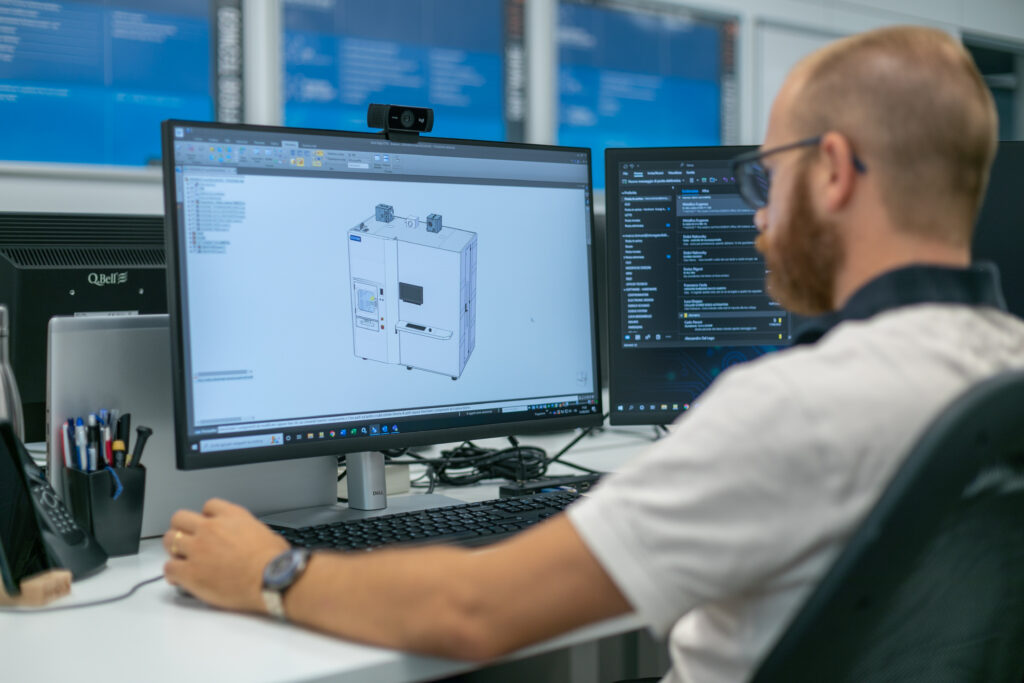

In the history of product development, Essegi Automation quickly recognized the importance of combining modular and scalable hardware configurations with the flexibility of a management system that is open to seamless integration with other existing systems in the company, ranging from ERP to MES to pick and place production lines.

This design methodology allows companies of all sizes and production capacities to rely on an advanced information control and management system that safeguards them from inefficiencies, human errors, and disruptions in the production flow.

Every growth perspective finds a strong ally in Essegi Automation’s integrated management systems, capable of addressing not only the most complex challenges in terms of efficiency and reliability (just-in-time), but also unforeseen critical situations (just-in-case), or a combination of the two!

Process partner in any case!