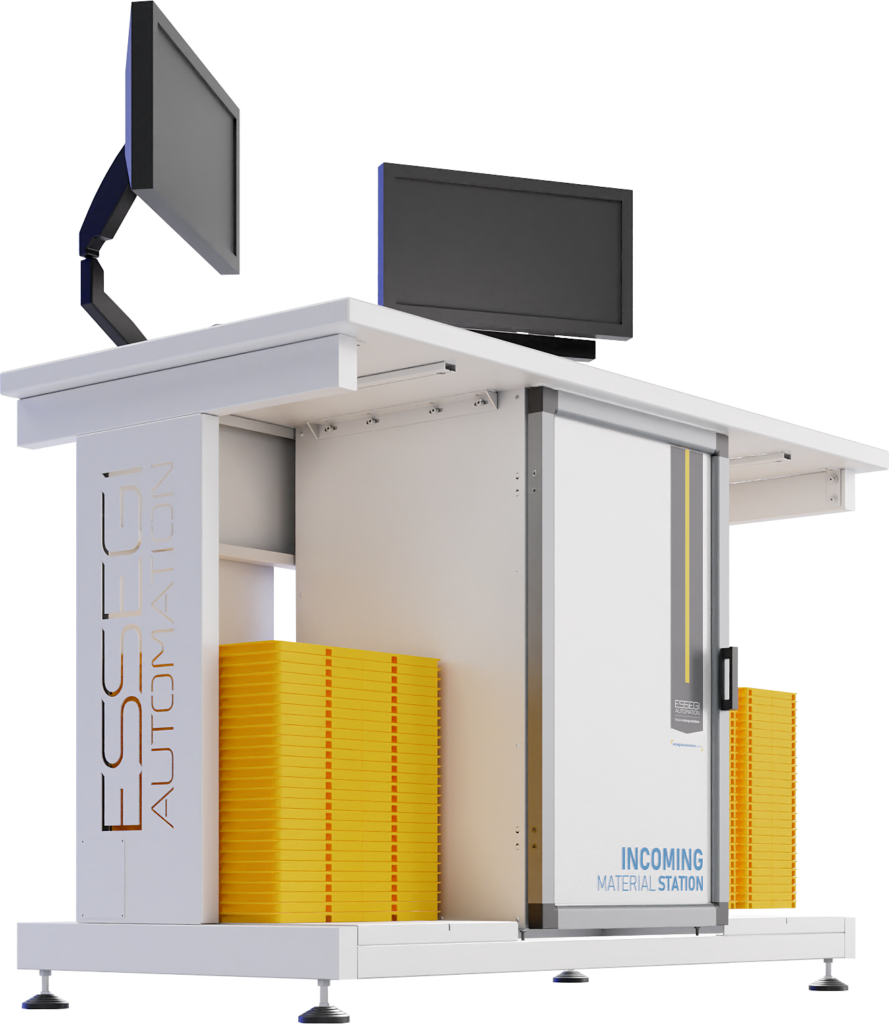

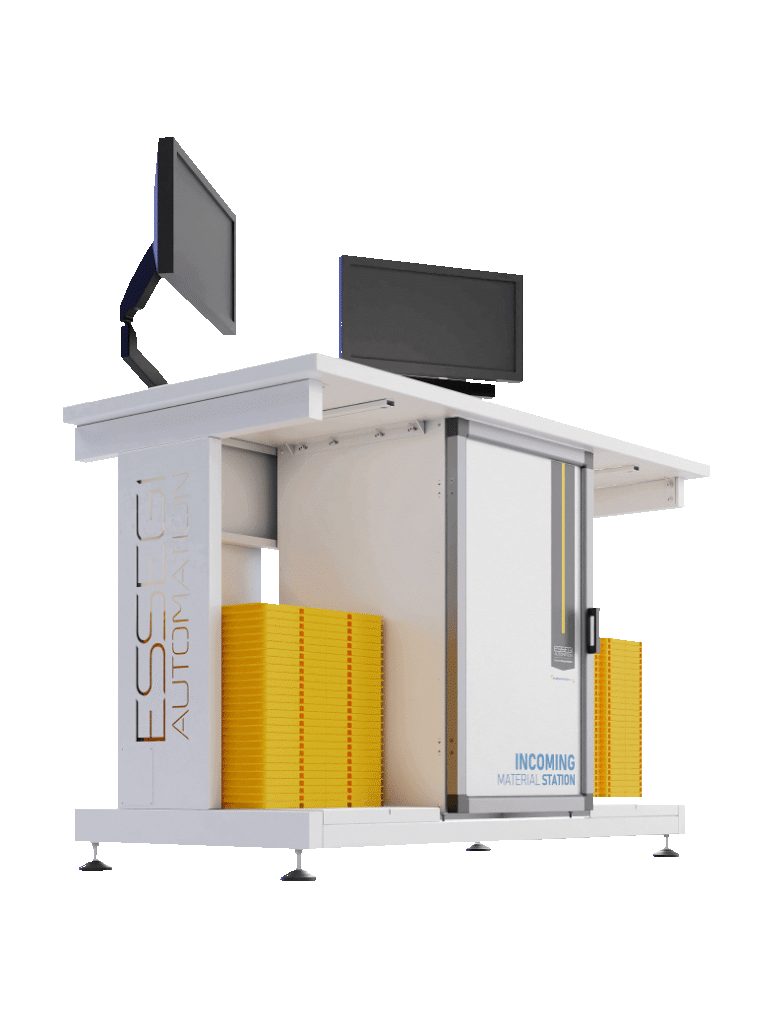

Incoming Material Station

The advanced solution for the management of the material in the acceptance phase. The precise, fast and integrated system to track the incoming information in a complete and reliable way.

- sturdy metal structure with antistatic work surface made of static dissipative laminate, with resistivity of 10M Ohm

- high-resolution camera that allows you to scan the information on the manufacturer’s label

- printer for the generation of a unique progressive ID code

- customizable labels according to your needs

- automatically import supplier and / or customer label information into the ERP

- generate a unique progressive code to identify the reel and the electronic components

- place the material on the table and read all the necessary codes and information

- take a picture and store it in the database for future viewing and quality checks

- update purchase orders in real time with the quantities of incoming materia

- send the information to the management system with a click.

- Interfacing with company ERP MES Pick and place systems

Benefits

Functionality

Track and archive the complete image of the reel and not just the label The camera records and stores the images of the reels placed on the shelf.

The camera records and stores the images of the reels placed on the shelf.

The images (the first and last record) will be displayed on the reel tags of the ISM software.

All images are saved on a hard drive in your systems, in fully configurable folders.

Automatically checks that the incoming material matches the transport document, or the order entered in the management system

The system verifies the correspondence between the incoming materials and the data entered in the management system (the purchase order or the packing list). Thanks to an interface with your ERP systems, the lines of open purchase orders or packing lists are updated in real time. The result is that in advance and with a single operation, the material actually requested and delivered is checked against the missing or excess material.

Validate qualified and approved part numbers

The ISM software checks the correspondence between the item codes of the new incoming material against a list of approved item codes. The software will prevent initialization of material that is not in the approved part number list ensuring extreme process and product quality.

It recognizes, analyses and stores 1D / 2D codes on the top of the reels

The camera and software are able to recognize, analyse and store any 1D / 2D code on the top of the reels. The software is set up with standard rules used by most component suppliers to label their products (available field: Part number, unique ID, case format, quantity, Bin, date, MSL, Manufacture PN, lot number, date of expiration, supplier, Order Ref., Notes field, custom field).

It manages in an advanced way the information present on the transport documents

Not only reels and labels but also documents. The form is ready to include the scanning and digitization of the data present in the documents.

- Scanning and saving/archiving of multipage transport documents or POs

- Create rules to extract data from documents such as document number, item code list, quantity, etc. (both 1D, 2D and text codes)

- View PO lines, user completion percentage and acceptance operator performance via the advanced dashboard.

Versions and accessories

Auto-incoming table

Independent unit, which does not necessarily have to be connected to another warehouse

Technical data sheet with the different storage capacity